Variable speed in applications

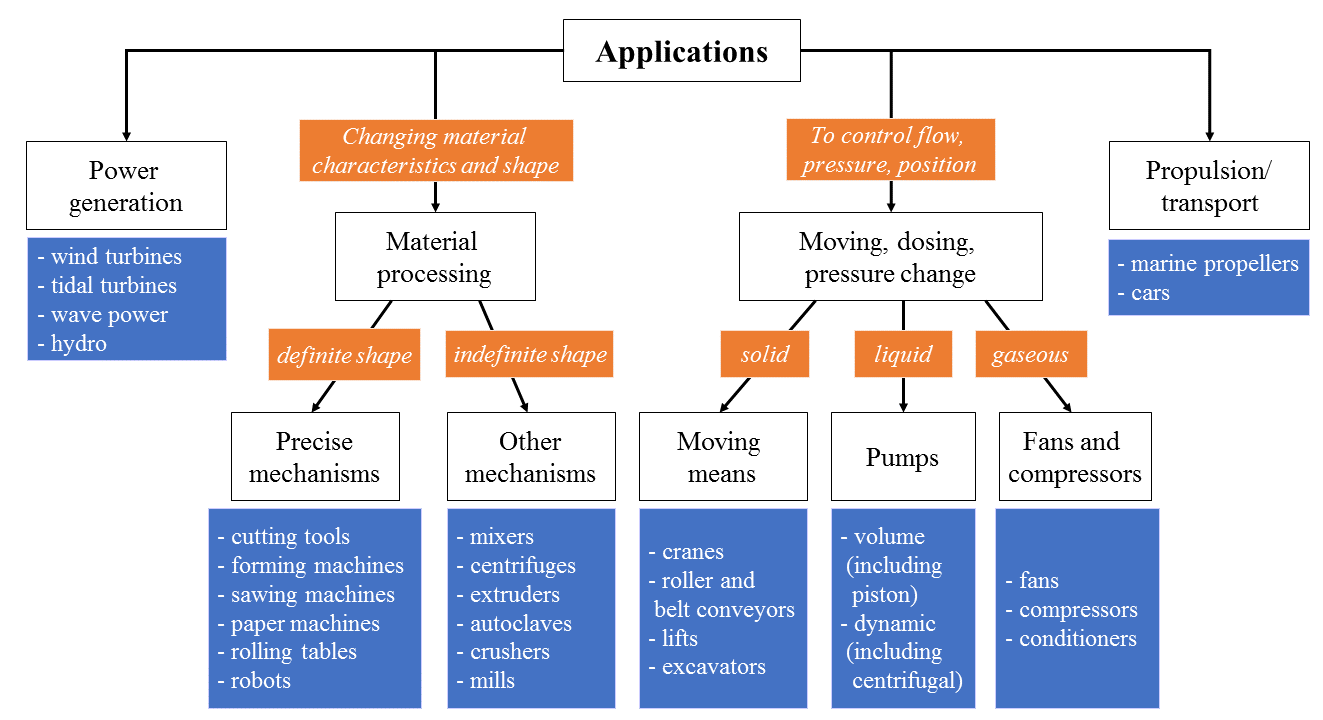

A motor controlled by a frequency converter (FC) has become a commodity. This is due to the number of advantages that provide the regulation of the motor speed and, accordingly, the driven mechanism's speed. The range of applications for variable speed drives (VSD) is very broad: general industry and utilities, defense and aerospace, transport and power generation, household appliances, etc. One of the possible classifications of the applications is presented in Fig. 1.

Fig. 1. Classification of the applications where VSD are used.

In many cases electric drive systems are designed for variable-speed operation. For example, the drive of a paper machine where high-precision synchronization and speed control of the multiple motors is required to produce paper of a specified quality, or a "flying shears" drive in metallurgy used to cut the moving sheet of metal. Also, in many cases, frequency converters are installed on existing standard induction motors.

Usually, one or more of the following goals are pursued:

Energy saving

In many processes, significant energy savings can be achieved if at each instant of time the speed is optimized for the given operating point. For example, a fan operating at 50% of the nominal speed consumes less than 15% of its rated power.

Process control, optimization, monitoring

Modern frequency converters have a wide range of functions that, along with speed control of the electric motor, also allow the transfer to the top-level automation system of all necessary information on the motor operation, remote control and monitoring. This allows full control of the operation of the regulated unit and, as a result, optimization of the production process as a whole. The result can be improved quality, increased output, reduced equipment downtime, etc.

Extended equipment lifetime

Smooth start-up and shutdown of the unit, provided by the FC, significantly extends the service life of the electric motor and the driven mechanism and increases the time between overhauls, thanks to the absence of current spikes and mechanical shocks and jerks. In addition, the drive provides a set of motor protections, such as protection against overheating, jamming, long overloads, etc.

Ease of servicing the whole set of equipment

The frequency converter does not require much of maintenance. At the same time, the installation of the FC allows in many cases to simplify the operation of many components of the system. For example, in water supply systems, smooth start-ups and shutdowns of pumping units, flow control with maintaining constant pressure, allows to eliminate hydraulic shocks, as well as reduce pressure in the pipeline. Due to this, the accident rate in the main line (pipe breaks, etc.) is significantly reduced.

Improvement of working conditions for the personnel

In many cases, when introducing frequency converters on fans, conveyors and a number of other mechanisms, it is possible to achieve noise reduction.