FC cooling

Typical efficiency of the low-voltage FC is 98% meaning 2% of converted energy is turned into heat which needs to be removed from the enclosed area. FC can be cooled by moving air and water (air- and liquid-cooling; AC and LC). The difference between AC and LC-cooled FC is in size and weight - higher compactness and lower weight can be achieved by use of liquid (water) cooling. AC and LC(=WC) FCs are usually priced on the same level.

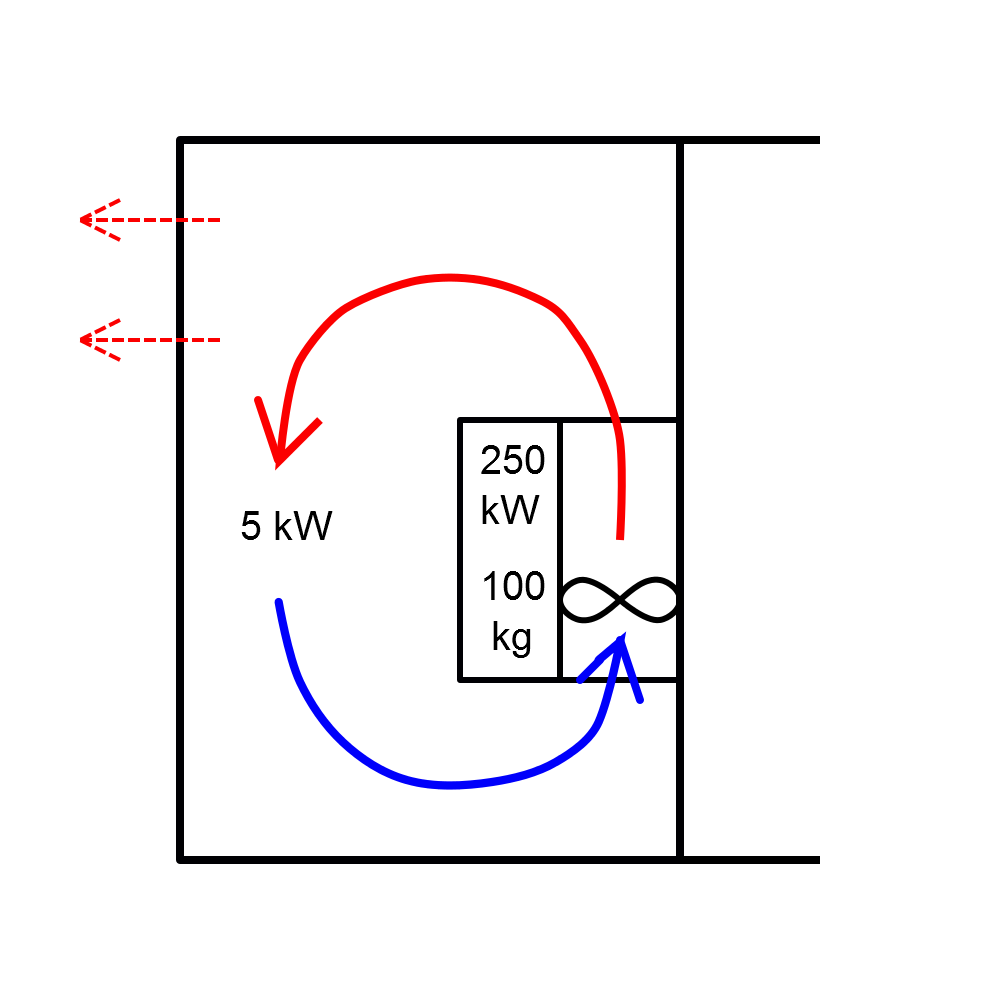

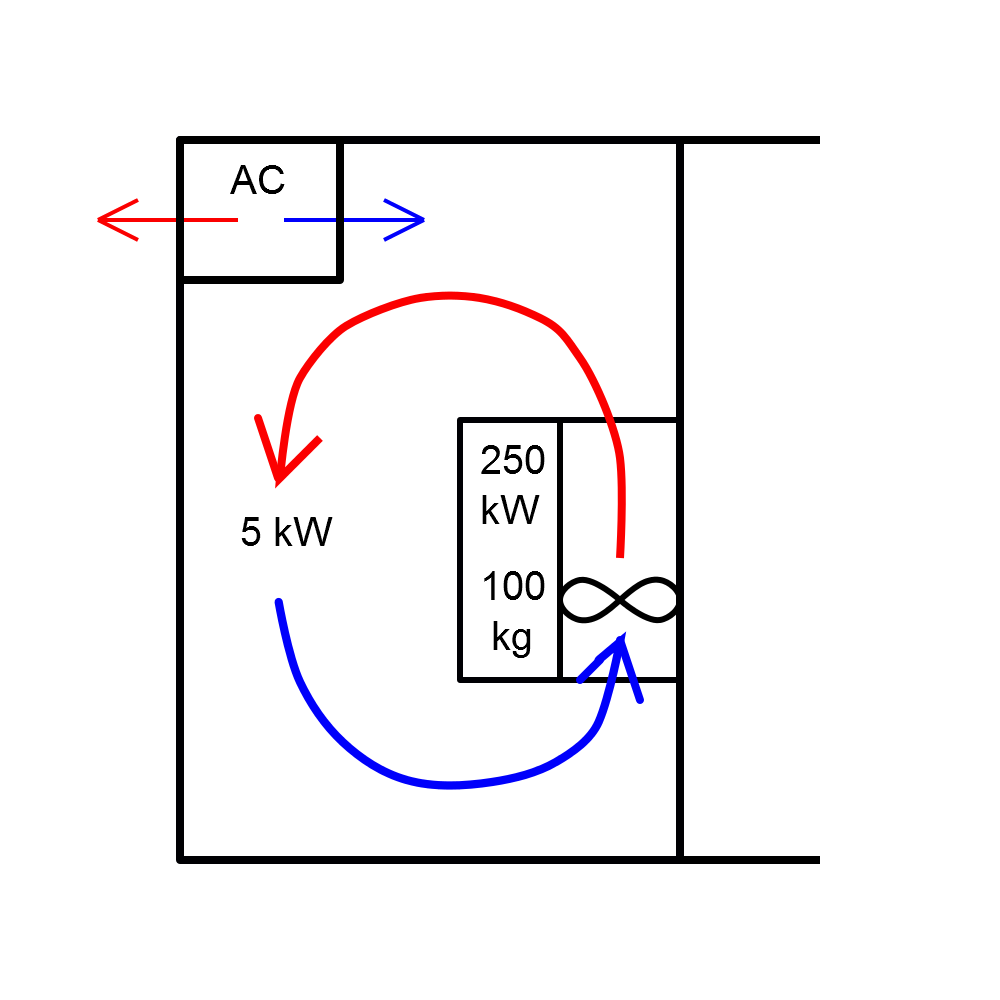

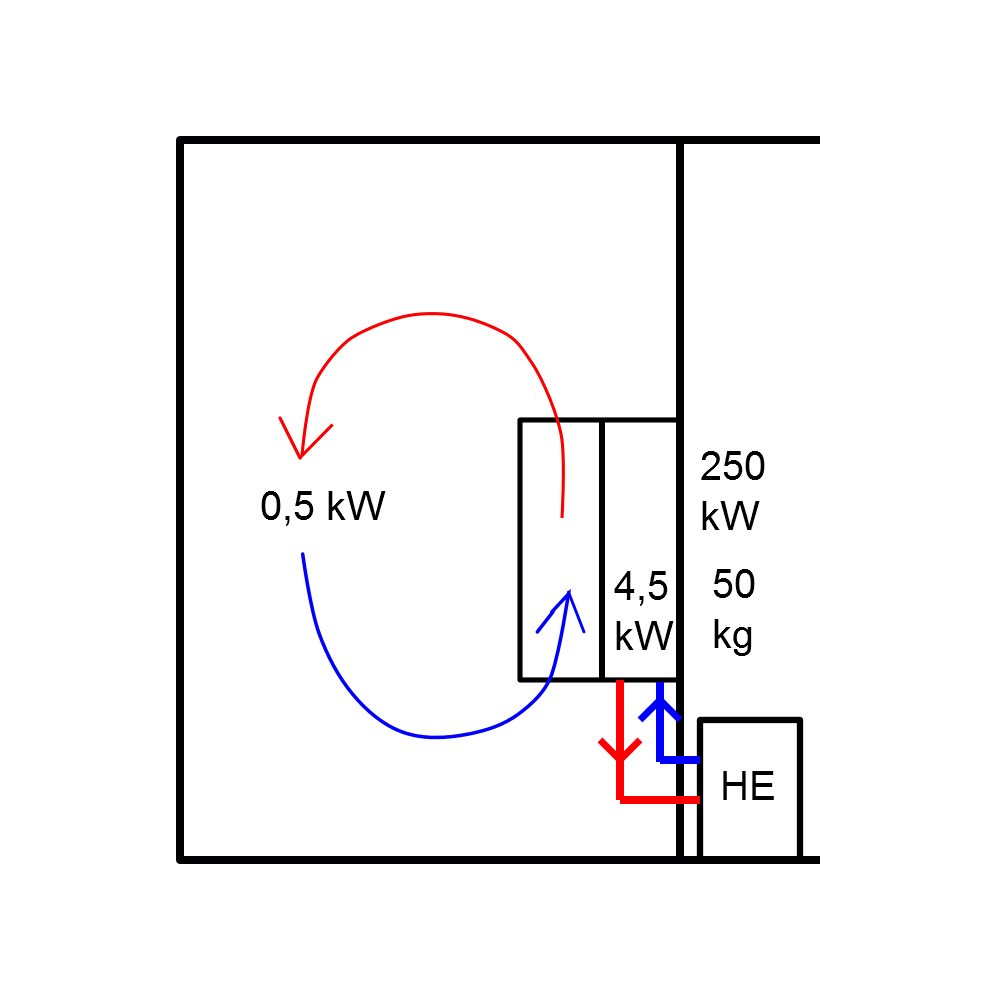

Fig.1 depicts a 250 kW low-voltage FC mounted on the wall in an enclosed area such as an electrical room.

(a)

(a)

(b)

(b)

(c)

(c)

Fig.1. Cooling types.

With the efficiency of 98% the 250 kW FC will produce 5 kW of heat. To remove the heat from the FC’s heatsink a quite powerful ventilation fan should be integrated into the FC enclosure. For the 250 kW power the volume of air pumped through the heatsink should be in the order of 2000-3000 m3/h. Filtering may be required if the environment is dusty or dirty. This can be a maintenance concern.

If the produced heat is not handled (removed) in some way, eventually the temperature within the enclosed area (ambient temperature for the FC) will increase. Increasing the ambient operating temperature above the maximum design temperature of the FC will cause the FC to overheat which shortens its lifetime and will cause shutdowns. In Fig.1,a the heat is removed in a natural way, e.g. through walls, windows, doors. This is possible if the enclosed area is large (e.g. large production hall). In Fig.1,b the heat is removed with the help of air conditioning. The latter measure can be costly and/or complicated to implement.

Fig. 1,c depicts water-cooled FC with water pipes going to the neighboring room. First, the water-cooled FC is considerably smaller (half the weight of the air-cooled one). Secondly, the heat produced inside the FC due to losses is divided into two parts; 90% is removed from the heat sink by the cooling water and brought away from the enclosed area where the FC is installed, 10% are dissipated within the enclosed area. The 10% of 5 kW of heat make just 500 W, which can be easily dissipated without additional measures like air conditioning. So, the largest portion of heat is removed through the liquid and can be transferred to another media through a heat exchanger as shown in Fig.1,c.

Liquids used in the FC primary cooling loop. Typical: drinking water, demineralized or deionized water, and a water/glycol mixture for freeze protection.

Fig.2. Example of cabinet with LC FC.1

Fig.2. Example of cabinet with LC FC.1

Heat exchangers

If clean cooling water is not available on site, water-to-air or water-to-water heat exchanger may be used, providing clean water. Parameters of the heat exchanger such as size, weight, cost and losses need to be included in the system parameters/ performances when benchmarking alternative systems (cooling solutions). Liquid to liquid (water-to-water) heat exchangers are used when a cooling liquid is readily available. Liquid to air (water-to-air) heat exchangers are used primarily when air conditioning is not desired, or in dusty/dirty environments where air cooled VFD’s can be adversely affected by these conditions (plugged heat sinks, electronics covered in dust, complicated maintenance routines. Challenges of water cooling: condensation, electrochemical corrosion (mostly related to HEx)

Other factors to consider:

- Relation between cooling and IP

- Audible noise. The large fan is the primary reason air cooled FCs are noisy. There is no large air fan in LC FC, just a very small fans to cool the electronic boards