FC power, voltage and current

Rated power

FC are rated according to IEC standard 1. The series of powers in DriveConstructor is 1.1, 1.5, 2.2, 3, 4, 5.5, 7.5, 11, 15, 18.5, 22, 30, 37, 45, 55, 75, 90, 110, 132, 160, 200, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710, 800, 900, 1000, 1250, 1400, 1600, 2000, 2500, 3150, 4000 kW. If it is desirable that power is chosen automatically then choose "any" - it is the default setting.

Rated voltage

The same voltage ranges are given both for grid side and machine side of the converter. In DriveConstructor the variants to choose from are: 380-440, 650-700, 3200-3400, 5900-6700, 9000-12000 V. If it is desirable that voltage is chosen automatically then choose "any" - it is the default setting.

In DriveConstructor 3L-NPC topologies can have voltage rating of 2460 V, 3300 V and 4160 V, while ML-SCHB topologies – 6000 V, 6600 V, 10000 V and 11000 V.

Currents

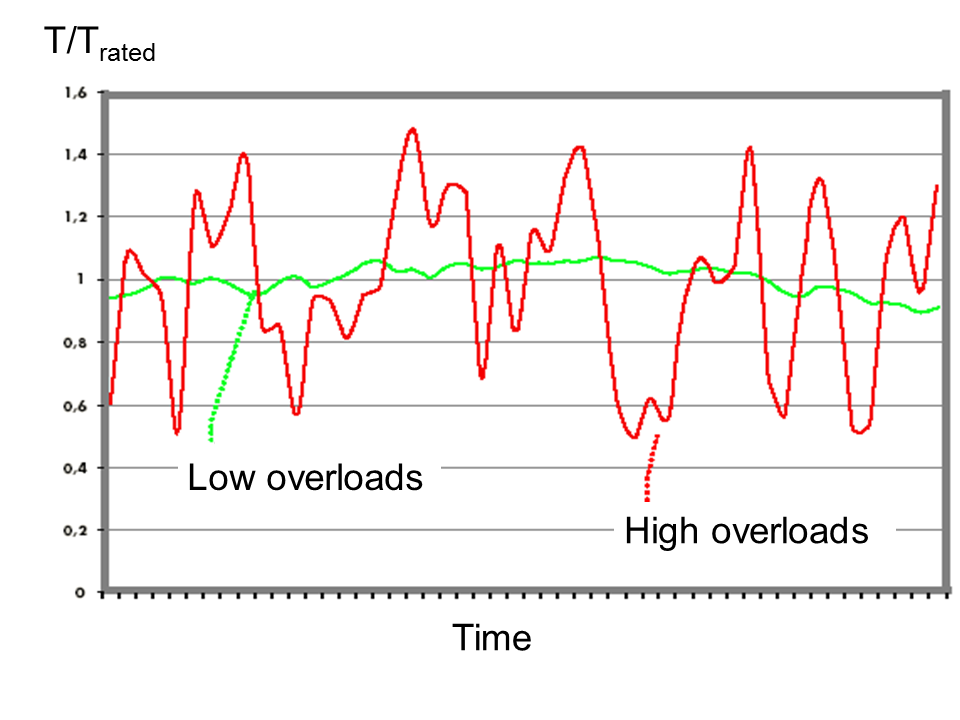

For almost any application it can be expected that load torque will vary with time going up and down. The pattern can be quite unpredictable. As current drawn from the FC is proportional to the load torque, the torque variation determines the current variation. In some application, e.g. pumps, the variation is not significant and can be called "low", while in other applications, e.g. conveyor or winch, the variation can be significant, and, therefore can be called "high". Examples of what can be called "high overloads" and "low overloads" are presented in Fig.1.

Fig.1. "High overloads" and "low overloads".

Fig.1. "High overloads" and "low overloads".

Choosing the FC the designer should take this aspect into account. Each FC has certain overload capability determined by several physical limitations such as thermal current and maximum current. The overloads the FC can tolerate will be characterized by a certain amplitude, duration and cycle.

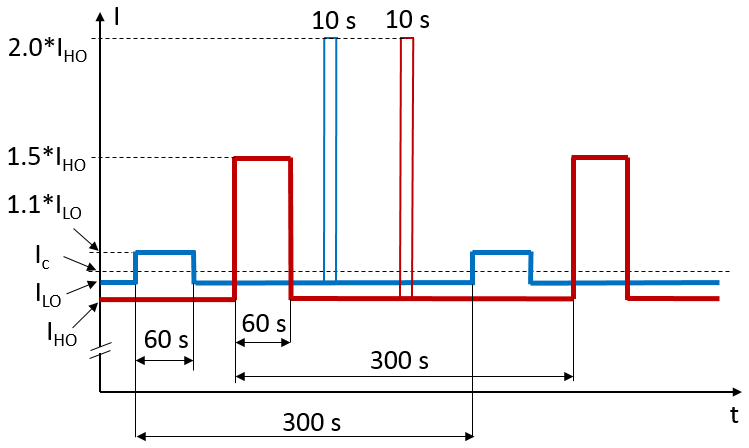

The same converter can be used for "high overloads (HO)" and "low overloads (LO)" but its rated current in a catalogue will be presented in two variants; and , where is always higher than . The principle is that motor current should be lower than FC current. When choosing FC for LO application, e.g. a pump, should be used and should be higher than . Usually for LO applications acceptable overloads are just 10% and FC current should then handle . When choosing FC for HO application, e.g. a conveyor, should be used and should be higher than . Usually for HO applications acceptable overloads are 50% and FC current should then handle .

Explanation is presented in Fig.2. Note which is rated continuous current, which is not used in practice. Short-term (10 s) high current of up to 200% of is acceptable for any converter.

Fig.2. Current overloads of conventional FC.

Fig.2. Current overloads of conventional FC.