Key parameters of electric machines

Rated power

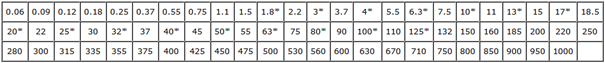

Power rating of the electric machines available in DriveConstructor is according to IEC 60072-1 which suggests the following preferred ratings (based on a subset of the R40 series) for motors (in kW) and generators (in kVA):

Note that asterix-marked powers are "secondary series" ratings and are only to be used in cases of special need. 1

In DriveConstructor we use the following series of powers (in kW): 1.1, 1.5, 2.2, 3, 4, 5.5, 7.5, 11, 15, 18.5, 22, 30, 37, 45, 55, 75, 90, 110, 132, 160, 200, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710, 800, 900, 1000, 1250, 1400, 1600, 2000, 2500, 3150, 4000.

Our list is shorter than the IEC one as we picked up only the most used powers.

Rated voltage

Electric machines may be designed for different supply voltages (from converter or grid). Machines are usually designed for «standard» ranges of rated voltage, e.g. 380-400 V or 650-700 V, as it is easier to connect a «standard» machine to a typical grid or a «standard» frequency converter. In Europe and America the standard ranges are different. In Europe it is usual to differentiate between LV (below 1 kV) and MV (above 1 kV).

In DriveConstructor the range of rated voltages to which the machine is designed to operate within can be chosen from the following options: 380-440, 650-700, 3200-3400, 5900-6700, 9000-12000 V. If it is desirable that the voltage is chosen automatically then choose "any". It is assumed that all machines are Y-connected. In practice windings can be reconnected into D, but this option is not included.

Machines designed for lower voltage are usually smaller, lighter and cheaper than those designed for MV. This is because of thinner insulation in the slots, which allows putting more copper in the slots and makes heat removal easier.

It is normally not possible to design LV machines for very high powers as currents would become too high and cables would become too thick to be practical. LV machines are normally produced for powers from fractions of kW up to a few MW (in DriveConstructor up to 2 MW), MV machines – from about 0,2 MW to 10...20 MW (in DriveConstructor up to 5 MW), in some cases up to 100 MW!

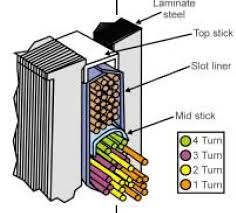

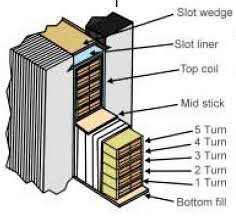

Slot designs of LV and MV machines look quite different:

Fig.1. LV slot.

Fig.1. LV slot.

Fig.2. HV slot.

Fig.2. HV slot.

Rated synchronous speed

Rated synchronous speed is proportional to supply frequency and reverse proportional to number of poles (). For 50 Hz supply and number of poles 2, 4, 6, 8 and 10 rated synchronous speed is 3000, 1500, 1000, 750 and 600, respectively.

SCIM have slip, so its rated speed is lower than rated synchronous speed by a few percent. SyRM and PMSM have rated speed equal rated synchronous speed.

It is obvious that a machine designed for delivering high power is bigger than a machine designed for delivering low power. It is less obvious that the rated speed the machine is designed for affects it’s weight, compactness, rotor inertia and cost. However, if the power is fixed, the machine with lower speed will have higher torque (). To be able to provide higher torque the machine has to be larger, heavier and as the consequence more expensive.