What is an optimal system

The system can be called optimal if it was benchmarked with alternative systems on one or several criteria and showed the best score on the criteria. The criteria can be cost (e.g. Capital Expenditures, CAPEX or Operational Expenditures, OPEX), efficiency (e.g. at rated load or at partial loads), size and weight, reliability, etc. The criteria should be relevant for the application. For example, for a pump cost will be one of the most important criteria, while weight will usually be much less important. For wind turbines both efficiency and weight will be important, leaving cost less important.

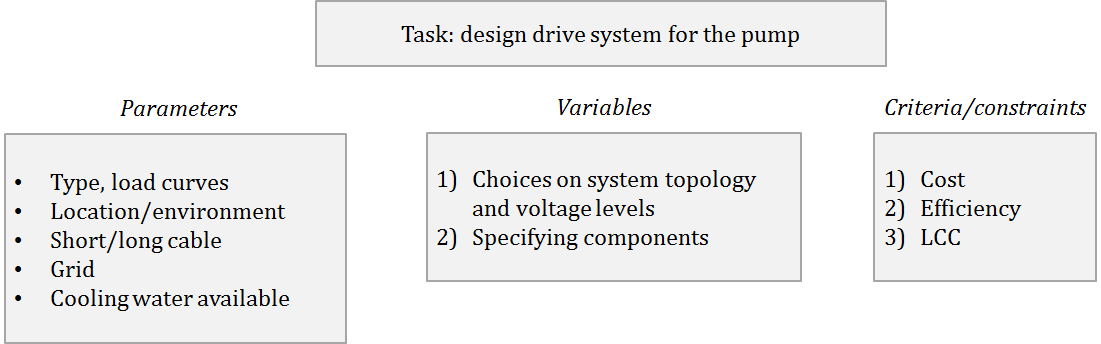

In the proposed Exercises the systems should be usually designed for one criterion. In Fig. 1 the list of criteria to choose from contains Cost, Efficiency and Life Cycle Cost (LCC).

Fig. 1. The task.

Fig. 1. The task.

The process of selection of the variables (system structure and components with concrete specification) to reach the best score on the chosen criterion can be called system optimization.

Benchmarking

As mentioned above, optimal system is selected in competition with alternative solutions, therefore, some benchmarking (comparison) method in needed. The benchmarking can be quantitative and qualitative, the latter being preferable.

Quantitative and qualitative comparisons

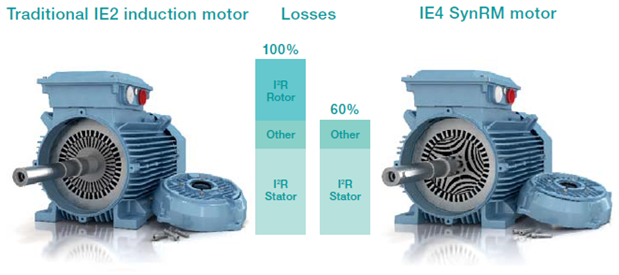

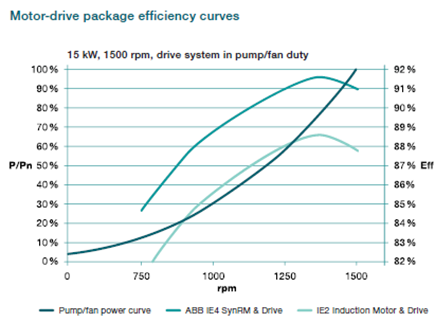

For example, motor technologies can be compared looking into loss mechanisms, etc (Fig.2). However, numbers reflecting the components and system behaviour in different operational aspects will provide a more credible answer. One of such measures is off course efficiency (including partial loads!). An example is shown in Fig.3.

Fig. 2. Qualitative comparison of motor technology.

Fig. 3. Comparing efficiencies.

Fig. 3. Comparing efficiencies.

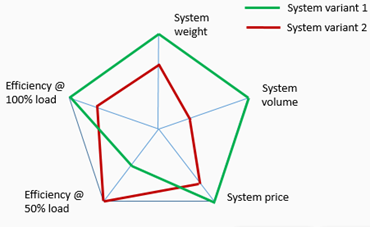

It is relatively easy to draw conclusions on which system is best (optimal) for the application when there is only one criterion, e.g. cost. It is more challenging to benchmark on several criteria. In such case Spider Diagram can be the right tool to visualize the results (Fig.4).

Fig. 4. Quantitative comparison.

Fig. 4. Quantitative comparison.

Life Cycle Cost (LCC)

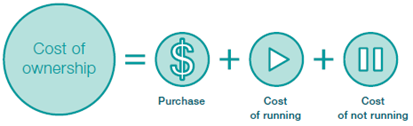

LCC is one of the popular criteria for benchmarking. Goodness of the EM for an application can be defined by cost of ownership which comprises purchase cost, cost of running (COR) and cost of not running (CONR). COR is cost of consumed energy which is defined by efficiency. CONR is defined by MTBF (reliability) which gives prediction of how often the machine will fail. CONR would include cost of repair and cost of stopped production. CONR is not included in DriveConstructor.

Fig. 5. Cost of ownership.

Fig. 5. Cost of ownership.