Mechanical design

Mounting variants

There are three basic variants of mounting included in DriveConstructor: B3 – foot-mounted, B5 – flange-mounted, B35 – machine with both feet and flange. The difference between mounting variants is reflected in price. Flange-mounted machine would have 1-3% higher price and flange&foot-mounted – by 5%, compared to the basic foot-mounted design.

Fig.1. B3 1

Fig.1. B3 1

Fig.2. B5

Fig.2. B5

Fig.3. B35

Fig.3. B35

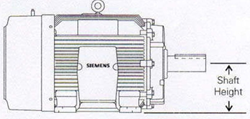

Shaft height

IEC and NEMA has standardized motor dimensions, including shaft height.

Fig.4. Shaft height illustration. 2

Fig.4. Shaft height illustration. 2

Standard shaft heights row in mm: 56, 63, 71, 80, 90, 100, 112, 132, 160, 180, 200, 225, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710. If the shaft height of the driven mechanism is set, then it can be beneficial to choose electric machine with the same or close shaft height to simplify coupling of the motor and the mechanism. If the shaft height of the driven mechanism is unknown then for the electric machine “any” can be chosen instead of some concrete value. Shaft height is approximately equal to half the diameter (h=OD/2).

Frame material

The available frame materials are used based on their mechanical strength, density, heat transfer capability, cost, corrosion resistance, etc. In DriveConstructor it is possible to choose from Aluminum (AL), Cast Iron (CI) and Steel (S). Some characteristics of the materials in comparison to the others are given below:

Aluminum

- vs CI&S: Aluminum is almost two-three times lighter than steel or cast iron but several times more expensive

- vs CI&S: Aluminum is a better heat conductor than steel or cast iron. The extrusion process enhances aluminum’s heat conducting properties by allowing the frame sections to have thinner fins placed closer together. The result is more fins and greater surface area for maximum cooling. So, machines with aluminum frames will be more compact and lighter

- vs CI&S: Machines with aluminum frames are usually cheaper and easier to install (because they are lighter).

Cast iron

- vs AL: Cast iron machines don't have corrosion problems. Their frames are much stronger than aluminum frames, but they are heavier and harder to install.

- vs S: Cast iron is cheaper than steel

Steel

- vs CI: The yield strength of steel is higher than the ultimate strength of cast iron. This makes steel much stronger and 250% more rigid than cast iron. Cast iron is perceived as a rugged motor frame material because of its bulkiness, when in reality its relatively fragile nature requires 2-1/2 times as much metal to approach the performance of steel. And when it comes to impact loads, steel provides much greater resistance to cracking.

Aluminum frames are usually used up to 60 kW, steel and cast iron frames – to MW level.