Combinations of stages

The stages can be put together in various combinations. Some examples are presented below.

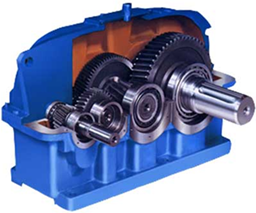

Gearboxes comprising several helical stages (Fig.1) are used generally in heavy-duty applications. They are quite efficient and can have many stages.

Fig.1. 3 helical stages. 1

Fig.1. 3 helical stages. 1

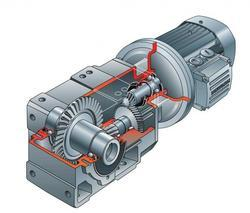

In the configuration presented in Fig.2 the input and output shafts are arranged at right angles via a gear set with either intersecting (bevel helical) or non-intersecting (hypoid) axes. The right-angle helical design ensures great space efficiency interms of width, and provides the primary alternative to worm reducers in applications involving right angle drives. They are characterized by high efficiency and can extend to extremely high reduction ratios (even to 1700:1).

Fig.2. 1 bevel and 2 helical stages. 2

Fig.2. 1 bevel and 2 helical stages. 2

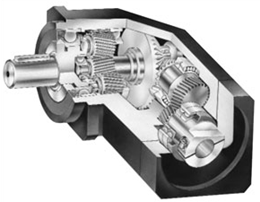

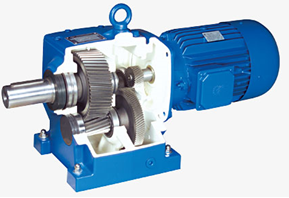

Some more examples are presented in Fig. 3-5.

Fig.3. Helical and bevel stages. 3

Fig.3. Helical and bevel stages. 3

Fig.4. Helical, bevel and planetary stages. 4

Fig.4. Helical, bevel and planetary stages. 4

Fig.5. Helical "inline". 5

Fig.5. Helical "inline". 5

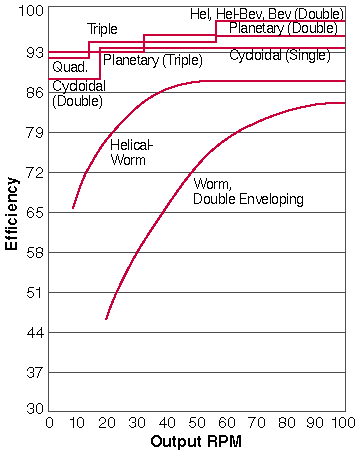

Efficiency of any combination is the product of efficiencies of the stages, therefore, efficiency of several stages is lower than single-stage solution. Fig.6 presents efficiencies of some combinations of stages. Note that lower rpm means higher gear ratio.

Fig.6. Efficiencies of various combinations.

Fig.6. Efficiencies of various combinations.