FC-2. Topology and voltage level

Imagine you are chief engineer at a large plant. You need to upgrade throttle regulated pumps driven by direct online started motors to speed-controlled systems with FC and without any throttles. You have available some motors on stock (imagine you have any motor you may need) but need to buy the FCs.

The pumps in question have different power: 0.5, 1, 2 and 5 MW.

- head 210 m, flow 200 l/s, efficiency 85%, rated speed 1450 rpm;

- head 210 m, flow 400 l/s, efficiency 85%, rated speed 1450 rpm;

- head 420 m, flow 400 l/s, efficiency 85%, rated speed 1450 rpm;

- head 800 m, flow 500 l/s, efficiency 85%, rated speed 1450 rpm.

Rated speed is the same – 1500 rpm. Grid – 6 kV. Distance between the pump and FC is 100 m.

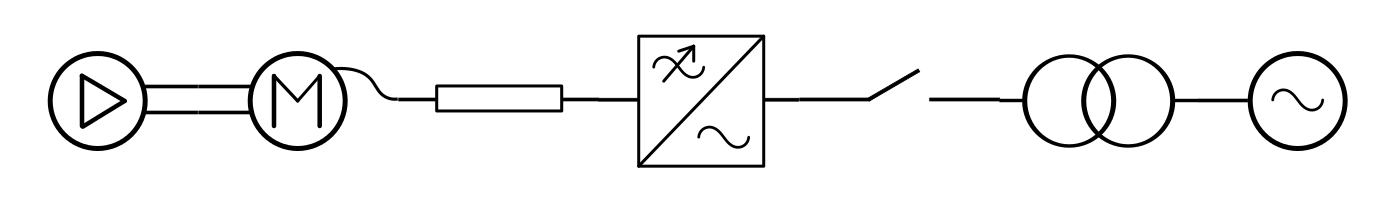

Use the system topology with a transformer:

You have constrained budget so design the system for lowest possible cost. Present the results in a table.

Reflect on how power level affects the choice of voltage level. Is the choice determined by feasible cable cross-section?

Find overall system efficiencies at partial load (50%) for each of the three systems.

Extra question: you've got MV motor with accessible termnical box which can be connected either Y or D. When connected "Y" it can be fed 6000 V, when "D" - 3400 V. How this reconnection possibility may affect FC choice/opportunities?