EM-2. Rated speed vs weight, size, inertia

You are chief engineer responsible for powering a new conveyor. You have three helical gearboxes available at the plant’s stock: two 1-stage gears with ratios 1:4 and 1:6, and one 2-stage gear (ratio 1:12). Your can buy a motor to match the gearbox or a motor that fits speed of the conveyor without any gearbox.

Consider two system architectures; with gearbox and without one (direct drive).

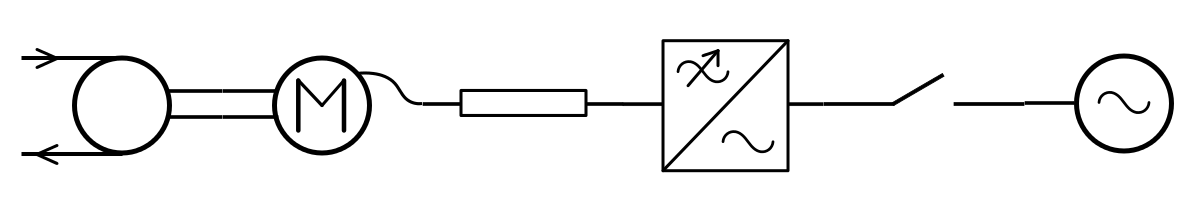

System 1:

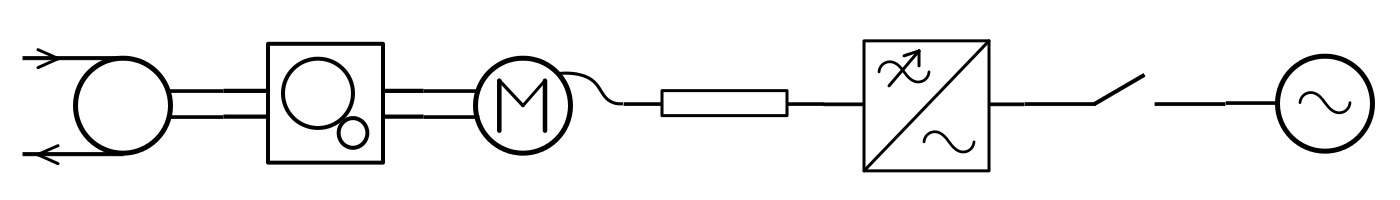

System 2:

For the systems 1 and 2 above investigate influence of the gear ratio on size, cost and inertia of electric motor.

- Take system 1.

- Set conveyor drum max speed to 230 rpm and min speed to 80 rpm.

- Torque = 9 kNm.

- Take the machine with synchronous speed to 300 rpm @ 50 Hz.

- Record weight, cost and inertia of the chosen motor.

- Take system 2.

- Set conveyor drum speed to 230 rpm and min speed to 80 rpm.

- Torque = 9 kNm.

- Record speed, weight, cost and inertia of motors for the following gearbox ratios: 4, 6 and 12.

Summarize in results in a table. Explain what you see, draw conclusions. Can you explain the results/conclusions as the electric machine designer?

Use PM machines only!