EM-3. Efficiency class, lifecycle analysis

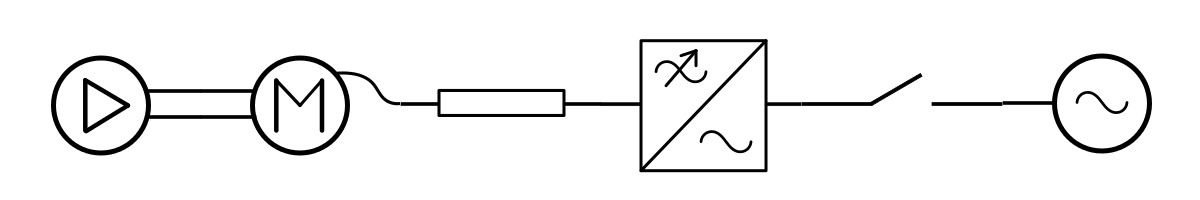

You are a chief engineer at a plant. Consider replacement of old induction motor (cooling IC411, protection IP21) on a centrifugal pump with either IE3 motor or IE4 motor. The old motor has efficiency corresponding to IE2. Available grid – 400 V. The existing motor is driven by an FC.

Pump parameters: head 50 m, flow 50 l/s, efficiency 82%, speed 1450 rpm.

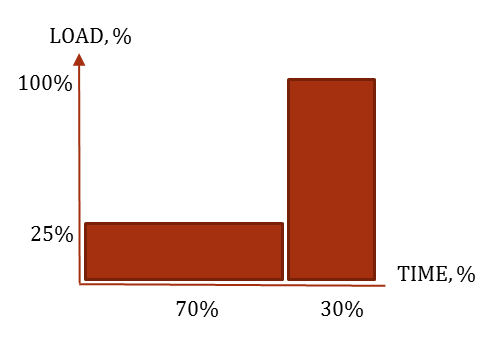

Operational mode of the pump:

- operation at 25% load 70% of time and at rated load - 30% of time

Find LCC (cost of ownership) for all the alternatives

- Energy price - 0,07 Euro/kWh (another variant 0,2 Euro/kWh)

- Operational time – 8000 hours/year

- Service life – 5 years (another variant 10 years)

So, there are all together eight variants to consider:

- IE3 motor, Energy price - 0,07 Euro/kWh, Service life – 5 years

- IE3 motor, Energy price - 0,07 Euro/kWh, Service life – 10 years

- IE3 motor, Energy price - 0,2 Euro/kWh, Service life – 5 years

- IE3 motor, Energy price - 0,2 Euro/kWh, Service life – 10 years

- IE4 motor, Energy price - 0,07 Euro/kWh, Service life – 5 years

- IE4 motor, Energy price - 0,07 Euro/kWh, Service life – 10 years

- IE4 motor, Energy price - 0,2 Euro/kWh, Service life – 5 years

- IE4 motor, Energy price - 0,2 Euro/kWh, Service life – 10 years

What motor (IE3 or IE4) would you choose for each of the four scenarios?

- Energy price - 0,07 Euro/kWh, Service life – 5 years

- Energy price - 0,07 Euro/kWh, Service life – 10 years

- Energy price - 0,2 Euro/kWh, Service life – 5 years

- Energy price - 0,2 Euro/kWh, Service life – 10 years

What general conclusion can you draw on dominating cost components?