Pumps

General description

A pump can be specified by its type and the set of hydrodynamic parameters; rated speed, head, flow, efficiency and density of the fluid it pumps. However, what dimensions the drive system is torque on shaft of the pump and the shaft's rated speed as well how the torque changes with the changing speed.

To configure the drive train for a pump DriveConstructor uses four parameters:

- Required rated torque on the shaft of the pump

- Rated rotational speed of the pump's shaft

- variable speed drive allows changing speed the pump operates at, however, a pump is designed for some definite rated speed usually given for any pump in the respective brochure or catalogue

- Load curve of the pump

- Starting torque of the pump

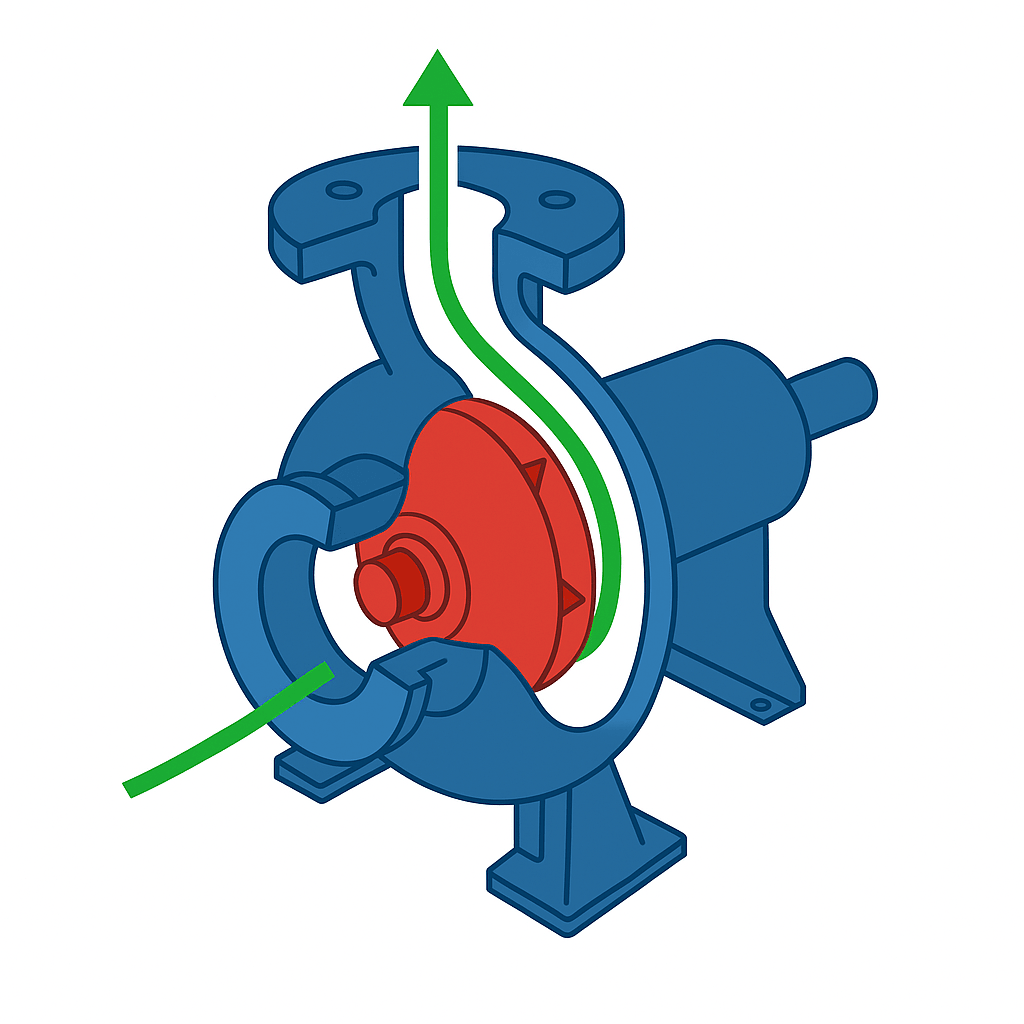

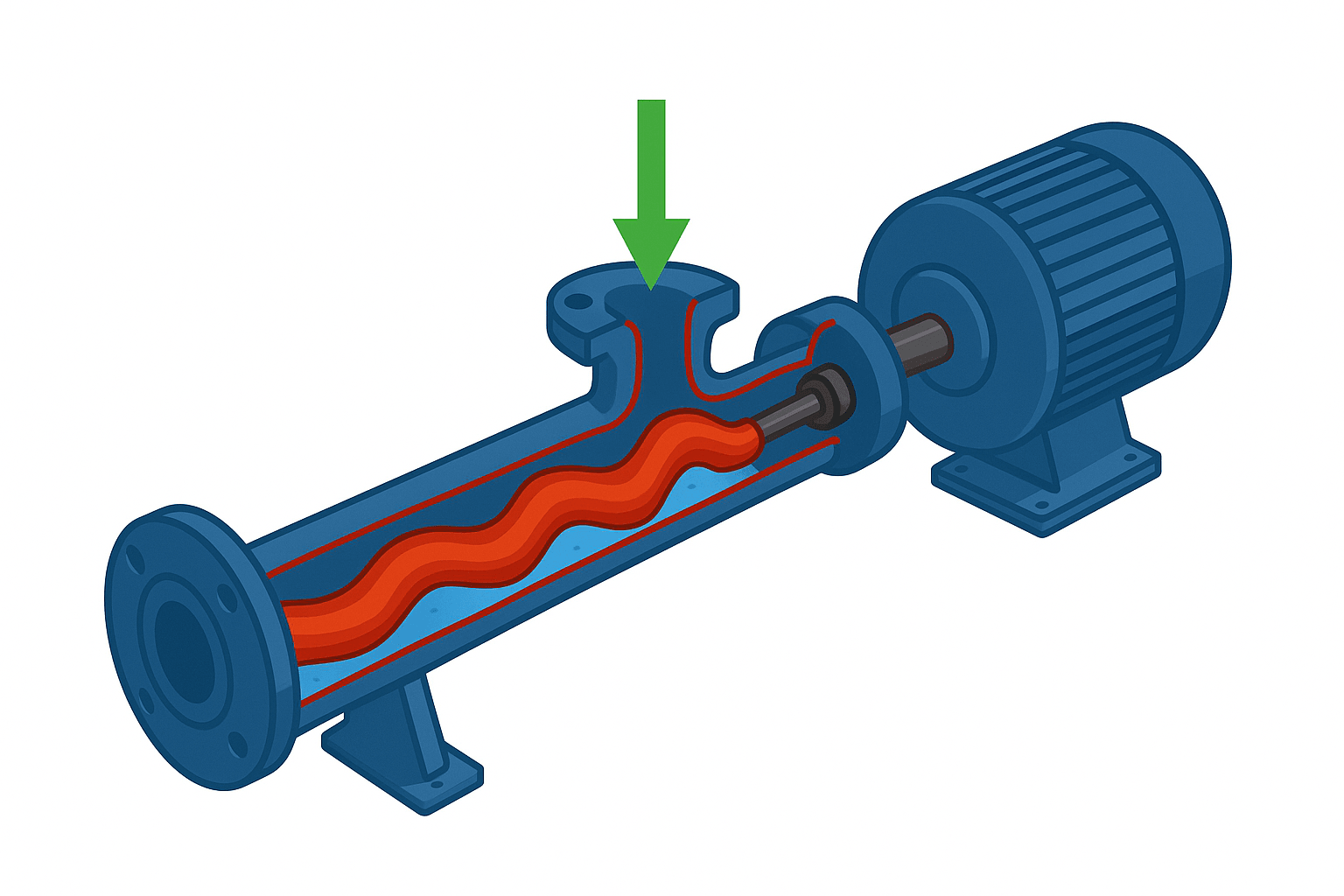

The load curve and starting torque of the pump depend on the pump's type. There exist many different types of pumps. The most common - centrifugal pump - is presented in Fig.1. Another example - progressive cavity pump - is presented in Fig.2.

Fig.1. Centrifugal pump.

Fig.2. Progressing cavity pump with a motor.

Rated rotational speed of the pump's shaft is given for any pump in the respective brochure or catalogue.

Rated torque

Rated torque is calculated from the power and the speed:

,

where is speed in rpm, is power in kW and is torque in kNm.

The power can be calculated from pump parameters such as head, flow, efficiency and density of pumped fluid:

,

where is in kW, is gravity ( ), is density of the pumped fluid in , is efficiency of the pump, is head in m and is flow in .

Note that in practice a pump can work at heads and flows lower than the rated ones for which it is designed. Speed and efficiency can then be different from the rated ones as well. So, remember to enter actual head, flow, speed and efficiency.